Add to Cart

SA214 ERW Carbon Steel , OD25.4X1.5WT KL Type Aluminum Refrigeration Tube

Detail:

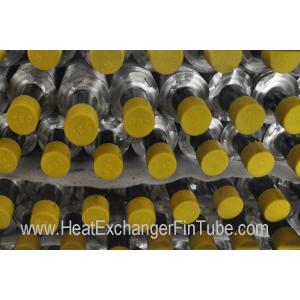

Protection of Ends

Both bare ends of Knurled Footed Fin Tubes shall be Zinc or Aluminum metalized applied by an electro spray arc system coating.

Application of SA214 ERW Tubes: For high, middle, low pressure boiler and pressure purpose

Surface treatment: Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting

| General KL Type production capacity | General specifications of KL Type fin tubes |

| Finning Facility: 7 finning machines; Daily capacity up to 5000 meters; | Tube OD: 50.8mm max. Tube Length: 18,000mm max. Fin Height: 16.5 mm max. Fin Thickness: generally 0.4mm ~0.6mm Fin Pitch: 2.1 mm (12FPI) min. |

Description:

Manufacturing process

The fin strip (normally aluminum) is folded into an ‘L’ shape and wound on to the base tube surface under tension. The surface of base tubes must be knurled before tension.The feet of the fins are joined together and cover the finned surface.

Acceptance Criteria

API Standard 661(Air-Cooled Heat Exchangers for General Refinery Service) or the delivery conditions (TDC) of clients.

Quality Test

The Overlapped Knurled Footed Fin Tubes quality is assured by hydrostatic or pneumatic tests, eddy current tests and tensile tests in order to verify the mechanical bonding between inner and outer tubes.

Accessories of KL type fin tubes

Tube Support Box, Clamp or Spacer Box (Materials: Aluminum, Zinc or Stainless Steel).

Delivery condition

Tube ends are square cut, free burrs, internally dried and air blown clean, externally coated with varnish at both ends of Overlapped Knurled Footed Fin Tubes.

The desiccants are put into each package for continental transportation as well.

Applications:

The common application fields are:

Specifications:

Knurled footed tube is combined with two different materials.

| Items | General Materials | Popular ASTM Materials |

| Core Tube Material | Carbon steel, Low-alloy steel, Stainless steel, Brass, copper, Cooper-nickel alloys, Aluminum bronze, Nickel alloys. | 1. Carbon Steel: A179, A192,SA210 Gr A1/C,A106 Gr B 2. Stainless Steel: TP304/304L,TP316/TP316L 3. Copper:UNS12200/UNS14200/UNS70600, CuNi70/30,CuNi 90/10 4. Titanium: B338 Gr 2 |

| Fins Material | Aluminum & Copper. | 1. Aluminum(Alu.1100,Alu.1060) 2. Copper. |

| All dimensions are in Inches and specification upon your requests. | |||

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch(Density) |

| 5/8 | 3/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/2 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| Please email for us for more information. | |||

Competitive Advantage: